Profile

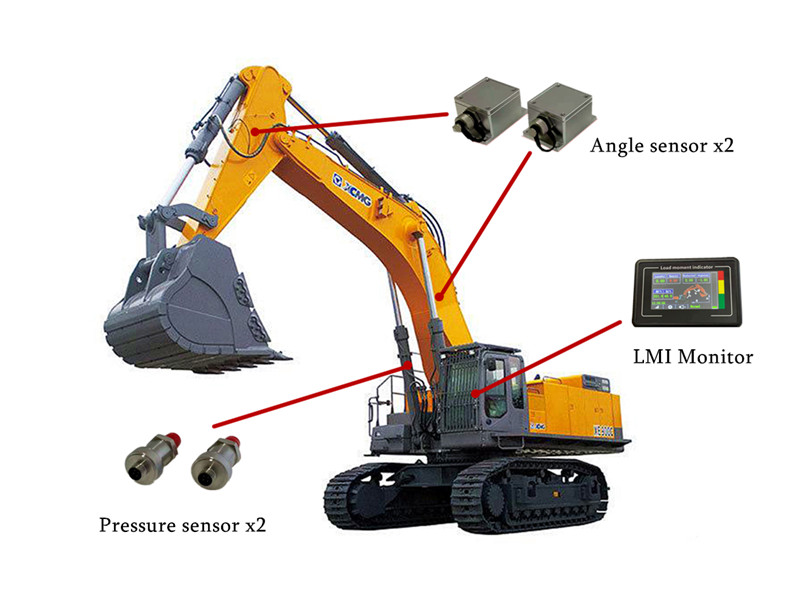

The system through the human-computer interaction interface and a variety of signal transducer, arm angle, height,working range, heavy weight and load information reflect to excavator operator, the work ability of the excavator in its design parameter range safety and efficient use/in realtime. When the excavator operation is closeto or beyond the scope of the security, the host will issue a sound and light alarm to remind the operator to stop illegal operations. If the operator is still illegal operation, the host will automatically lock the termination signal sent to dangerous operation direction of excavator arm.

Product Features

1.using the 4.3 inch TFT LCD with truecolor;

2.the hydraulic sensor adopts importedmovement with strong overload capacity;

3.using digital angle sensor;

4. using oil pressure of the poweralgorithm;

5. the main interface with a graphicaldisplay,sound and light alarm,automaticcontrol.

Parameter

| working voltage | DC 9v-36V |

| working temperature | -20°℃-+70°C; |

| storage temperature | -20°℃-+70°C; |

| system error | ≤±10%; |

| display error | ≤±10%; |

| relay contact capacity | AC220V 3A; |

| protection grade | IP65(other level of protection required customized) |

Components

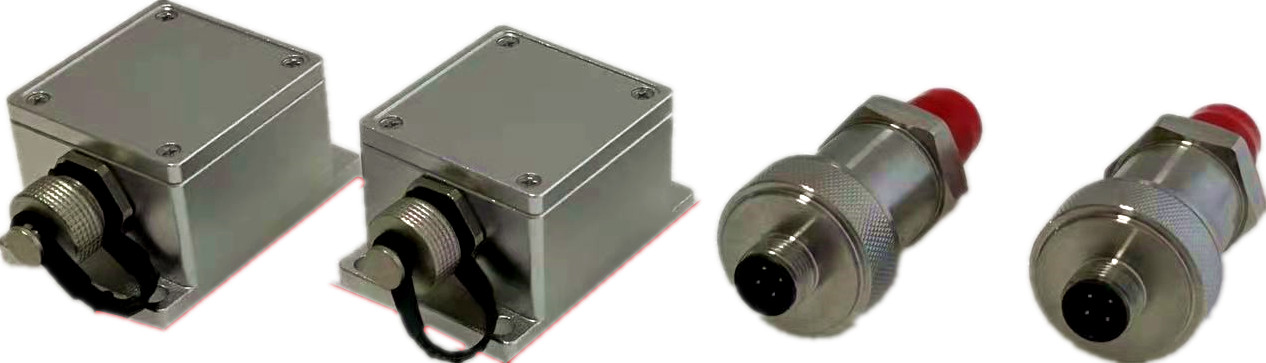

1.Angle sensor Angle sensor must fixed on the mounting plate, and the mounting plate welding on the excavator arm.

2.Pressure sensor Customers need to prepare a three-way connector for connecting our sensors, One sensor for each of the inlet and return pipes.

3.LMI monitor Come with a universal joint that can be used to secure the display to a 12- 18mm pole.

4.Interface definition dc-24v power (red:+24v ,blue: GND); buzzer; arm angle sensor; boom angle sensor; return pipes (OUT) pressure sensor; inlet pipes(IN) pressure sensor

Fault diagnosis

1. If the display does not display

Check the power supply line, Confirmation is 24v.

2. If no weight or anglesingle Check pressure sensor and line

3. If weight data Inaccurate Re-calibration NO-load data.