Tower crane safety management Integrated solution

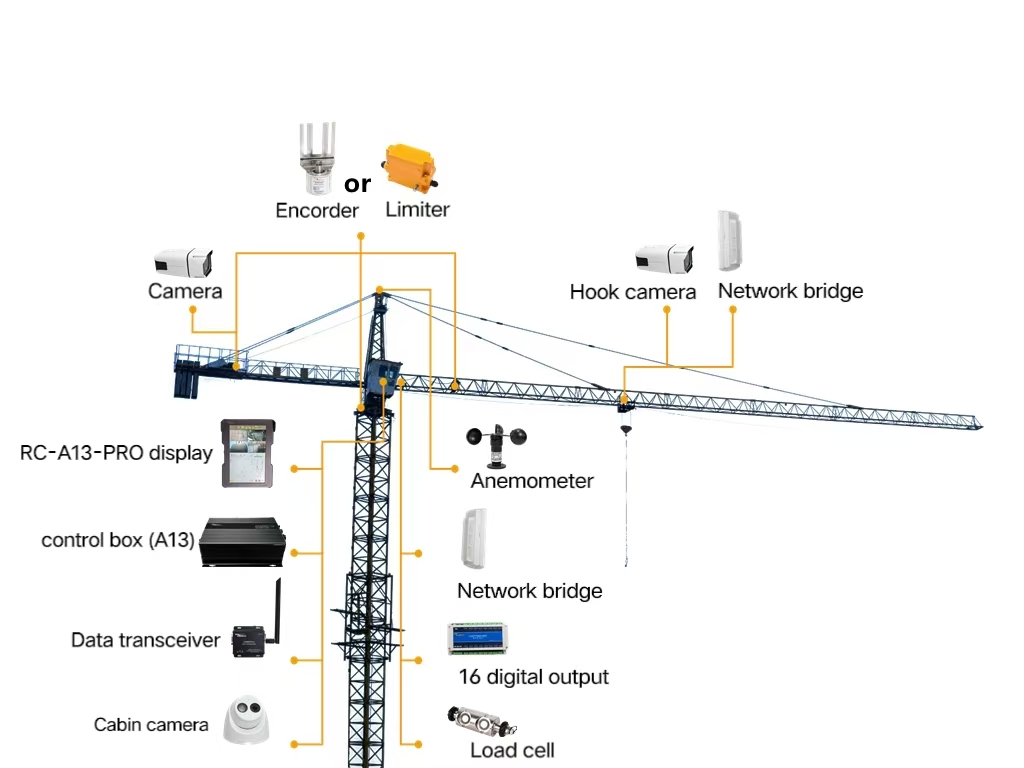

12.1-inch HD display integrates tower crane load moment indicator, anti-collision, hook camera, and black-box functions, solving the issue of traditional systems’ inability to share single screen.With over 200 types anti-collision algorithms and multi-scenario group tower Anti-collision, it is suitable for luffing, flat-top, and traveling tower crane mixed operations. It stores over 500,000 real-time records, with capacity of up to 30 days.

Moreover, the integrated hook camera system provides real-time tracking of the hook’s position, significantly reducing risks associated with blind lifts and lifting over obstacles. The display dynamically adjusts as the hook moves, keeping it centered and the load image as clear as possible. The system also includes features for monitoring the hoisting mechanism, trolley mechanism, and the operator’s cabin.

·Highly compatible sensor

It support automatic switching between analog and digital sensors and acompatible with various types of tower cranes to improve system applicability.

·Efficient model management

It supports to edit Excel document of tower crane parameters, zone parameters, and load characteristic tables. Users can easily modify and upload data to improve work efficiency.

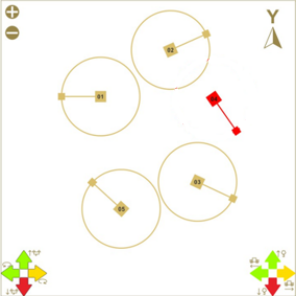

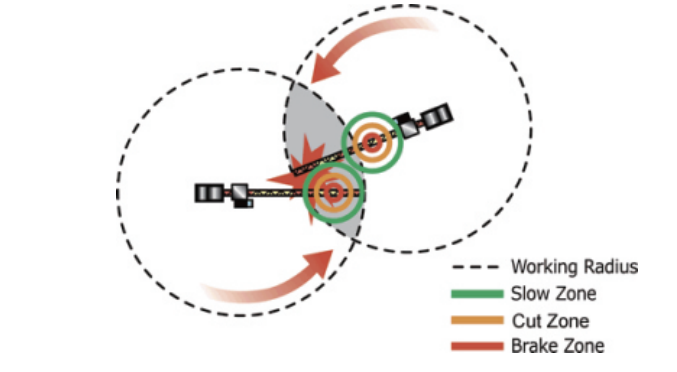

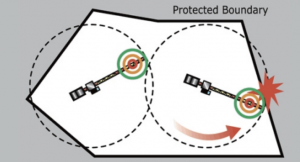

·Comprehensive zone protection

Obstacle coordinates can be generated with one click; single tower crane can set up 10 obstacle area, and support to set independent slewing limit to achieve more efficient control of tower crane’s operating boundaries.

·Off-line mode

Automatically set other off-line tower crane as zone (optional fixed-jib mode and max-working radius mode ) to eliminate potential collision risks and improve operating efficiency.

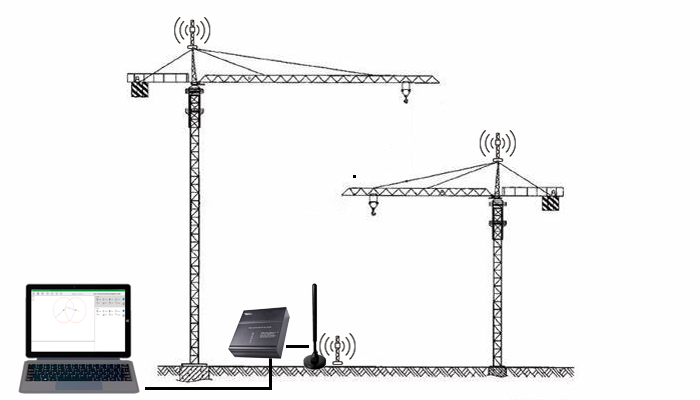

·Ground monitoring, remote communication

System transmits data via wireless radio. Users can master real-time working conditions of all tower cranes on current construction site in office and also quickly set or modify tower crane parameters (such as height) and zone parameters by ground monitor system. Calibrating sensor remotely without need for climb to improve debugging efficiency.

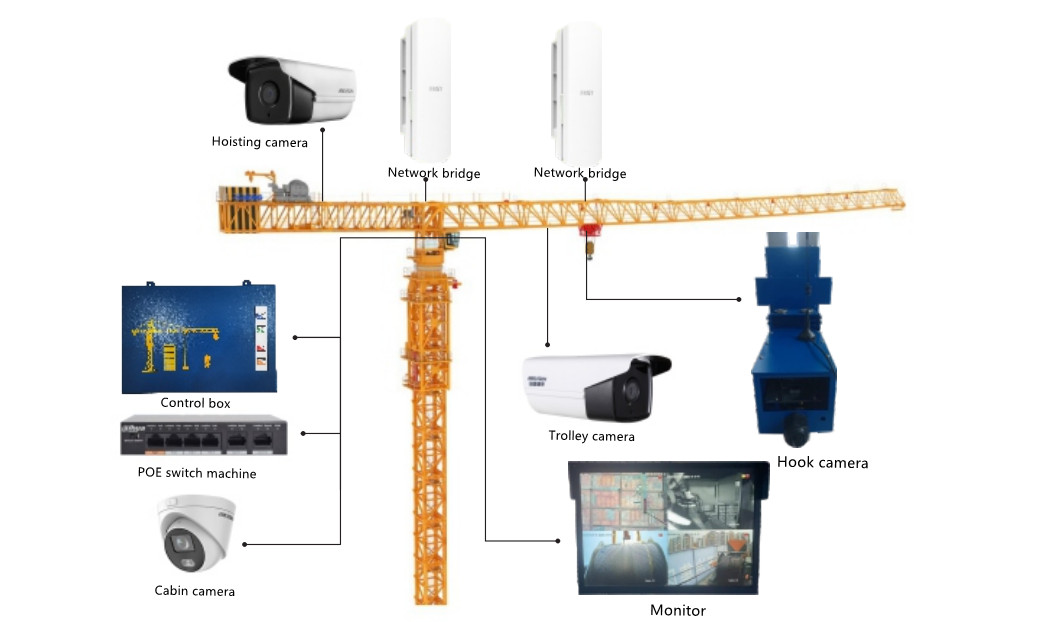

·Intelligent Camera system

Integrated hook camera system provides real-time tracking of the hook’s position, significantly reducing risks associated with blind lifts and lifting over obstacles. Monitoring winch in real-time to prevent entanglement;Monitoring Cab to avoid dangerous operations and other functions; video data can be connected to cloud and view remotely. 200w high-definition camera with up to 22x zoom can clearly see car license plates from 80m height, significantly improving safety and efficiency.